Leading Driveway Paving Contractor in Southern Maine

RJR Building Is Your Go-To Choice for Driveway Paving Contracting Services

Driveway Paving

RJR Building offers top-quality driveway paving contractor services to complement our comprehensive range of home improvement solutions. Trust us to elevate your property with professional driveway paving.

Lot Clearing

RJR Building offers professional lot-clearing contractor services as part of our complete range of services. Trust RJR Building to transform your property with precision and expertise.

Parking Lot Paving

RJR Building offers professional parking lot paving contractor services to ensure the durability and aesthetic appeal of commercial properties. Our meticulous attention to detail and efficient methods provide top-quality paving solutions, adding value and functionality to every project.

Rating

Rating

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Experience the best of paving contractor services in Southern Maine.

As professional paving contractors, our company specializes in installing, repairing, and maintaining paved surfaces such as driveways, parking lots, and walkways.

We use materials such as asphalt, concrete, and pavers to create a smooth and durable surface for our clients.

Contact the Pros At RJR Building, Your #1 Choice For A Paving Contractor in Southern Maine Today!

We provide quality paving in every new driveway, parking lot, and walkway, even down to the smallest details. So if you live in the greater Augusta area and find yourself searching for, "paving contractor near me", then you're in luck. Give us a call or fill out our contact form. We're eager to make your dream come to reality!

Our Paving Services and Processes

-

Asphalt Driveways

Are you in need of a driveway that is durable, eye-catching, and requires minimal maintenance? Look no further than asphalt. Made by combining rocks, sand, and liquid asphalt, this material is tough enough to withstand any weather and last for years.

At RJR Building, we specialize in installing asphalt driveways, and we're confident that we're the right team for the job. Here's how we do it:

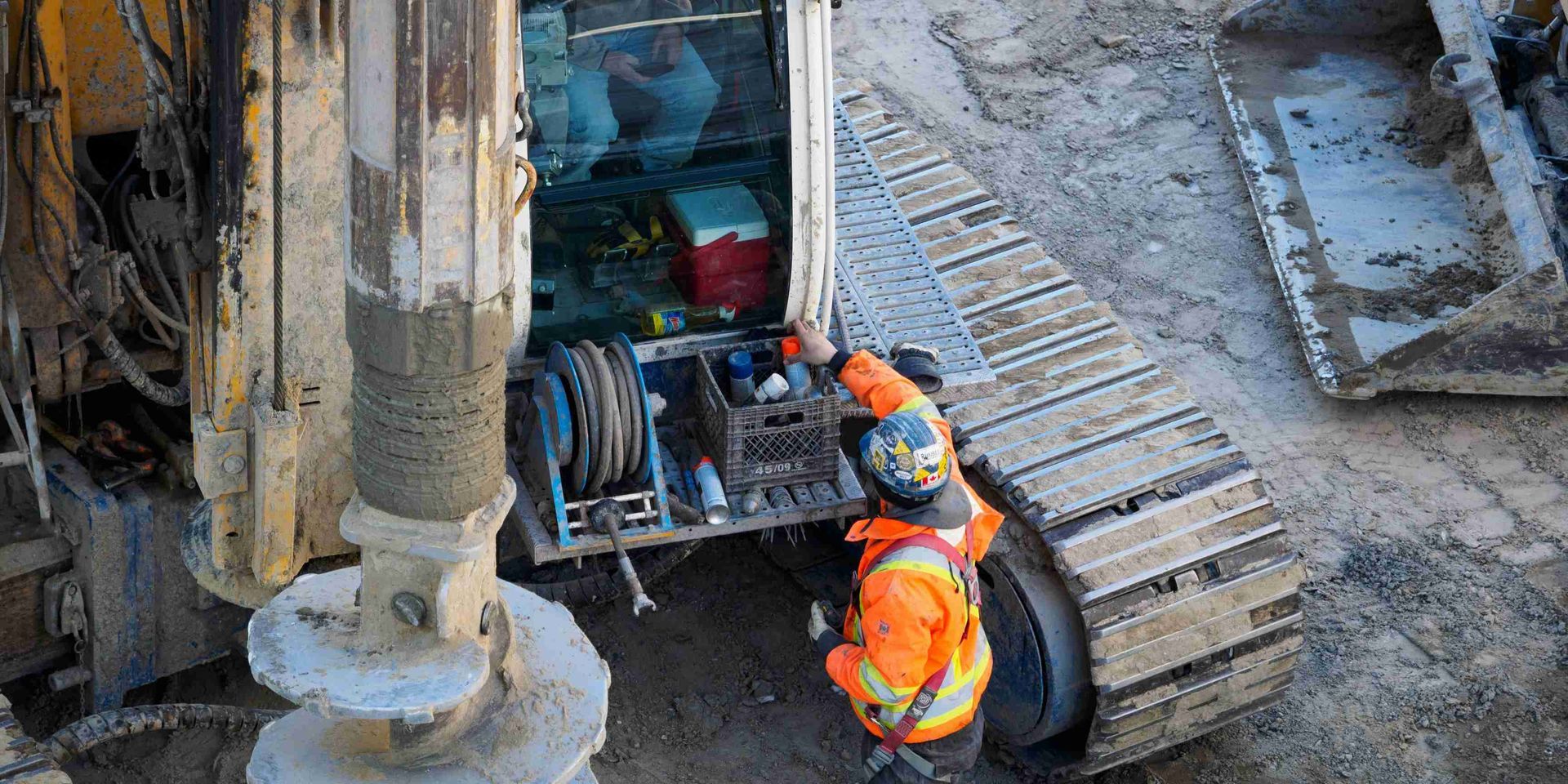

1. Demolition and Removal: Our heavy machinery can handle any old pavement, concrete, or pavers that need to be removed from your driveway. We dispose of the material, and whenever possible, we recycle it.

2. Grading and Sloping: Our team uses precision tools to ensure that your driveway is level and smooth. We also create a slight slope to prevent water from pooling and causing cracks.

3. Sub-Base Preparation: We create a sturdy and frost-proof base for the asphalt layer by laying down a thick layer of gravel or crushed stone and compressing it.

4. Asphalt Installation: Our experts heat the asphalt mix to over 300°F and spread it evenly over the base using a paving machine. We then use a roller to press and smooth the asphalt layer, creating a flat and firm surface that will last for years.

5. Drying and Curing: We allow the asphalt driveway to dry and harden for at least a day before it can be driven on. We also use signs and cones to mark the driveway and protect it from damage.

If you're ready to invest in a long-lasting, low-maintenance asphalt driveway, contact us at RJR Building today to receive a free quote and schedule your service. We're confident that you'll be thrilled with the results.

-

Parking Lots

Paving a parking lot is an intricate and demanding process that demands meticulous planning, preparation, and execution. The following are the main steps involved in paving a parking lot:

1. Site Evaluation: The first step is to conduct a thorough assessment of the existing pavement, drainage, soil, and utilities. This evaluation will help determine the scope of work, materials, and equipment required for the project.

2. Site Preparation: The next step is to remove all debris, vegetation, and obstacles from the site. Depending on the current condition of the pavement, it may require milling, patching, or removal. Additionally, the subgrade layer, which is the layer of soil beneath the pavement, may need to be compacted, stabilized, or graded to ensure a smooth and level surface.

3. Base Installation: The base layer is the crushed stone or gravel layer that supports the pavement. The base is spread and compacted over the subgrade using heavy machinery. The thickness and quality of the base depend on the traffic load and soil conditions of the site.

4. Paving: The final step is to apply the asphalt or concrete pavement over the base. The pavement is delivered by trucks and spread by pavers. Rollers then compact the pavement to achieve the desired density and smoothness. Depending on the project's design and specifications, the pavement may also need to be sealed, striped, or marked.

-

Tennis Courts

Paving a tennis court is a highly specialized and precise process that demands the highest quality, durability, and appearance standards. To achieve these standards, the process involves several crucial steps that must be executed with precision.

First, the site must be inspected to determine the best location, orientation, and size of the tennis court. The site must be flat, well-drained, and free of any obstructions or hazards. It should also comply with local zoning and building codes to ensure that the project is legally compliant.

Next, the site is prepared for pavement installation, which may involve clearing, grading, excavating, and leveling the area. The soil should be tested and treated to ensure adequate stability and drainage. The site should also be marked and measured to ensure accurate dimensions and alignment.

The base is the foundation of the tennis court and is made up of several layers of crushed stone or gravel. The base must be spread and compacted over the prepared site using heavy equipment. It must be smooth, level, and uniform to provide solid, even support for the pavement.

Finally, the pavement layer is applied over the base. The pavement can be asphalt or concrete, depending on the client's preference and budget. The pavement is delivered by trucks and laid by pavers.

The pavement is then compacted and cured to achieve the desired strength and smoothness. It must also meet the specifications and standards of the sport governing bodies, such as the International Tennis Federation (ITF).

By following these steps with precision and skill, a tennis court can be constructed to the highest possible standards, ensuring that it will provide years of enjoyment and meet the needs of players and spectators alike.

-

Sealcoating Services

Asphalt pavement is the backbone of your property, where you park your car, welcome guests, and enjoy outdoor activities. However, to keep it in top condition, regular maintenance and protection are essential. That's where our superior sealcoating services come in - we apply a thin layer of premium protective material to your pavement, shielding it from water, oil, sun, and other damaging elements.

Our sealcoating service also gives your pavement a stunning, brand-new appearance, adding substantial value and beauty to your property.

When you choose us for sealcoating, we follow a strict process to ensure the best possible service:

1. Cleaning: We clean your pavement thoroughly to prepare it for sealcoating. We use a blower, broom, and washer to remove any dirt, grass, stains, or other debris that could interfere with the process.

2. Crack filling: We fill any cracks in your pavement using a hot rubber filler that seals them and prevents water from penetrating further, which could cause additional damage.

3. Edging: We apply the sealcoat carefully along the edges of your pavement, where it meets the curb, sidewalk, lawn, or any other surface. We use a brush or squeegee to avoid spilling or spraying where it does not belong.

4. Sealcoating: We spray or squeegee the sealcoat over the entire pavement surface. We use a high-quality sealcoat that matches your pavement type and preferences. We apply two coats of sealcoat, allowing the first one to dry before applying the second.

5. Drying: We let the sealcoat dry and harden for at least a day before you can use your pavement again. We put up signs and barriers to keep cars and people off your pavement during this time.

By following these steps, we ensure that your pavement receives the best sealcoating service possible. Our sealcoating service will help your pavement last longer, look better, and save you money on repairs and maintenance.

Contact us today to get a free quote and book your sealcoating service with us. We guarantee that our sealcoating service will exceed your expectations, leaving you with a pavement that will last for years to come.

-

Out With the Old, In with The New

Reclaiming old asphalt is an exceptional, cost-effective, and environmentally friendly way to renew and enhance the pavement surface. This process involves the following steps:

1. Pulverizing: The old asphalt is broken up and mixed with the underlying base material using a large reclaimer machine. This results in a uniform and stable mixture that can be reshaped and compacted with confidence.

2. Grading: The reclaimed mixture is graded and leveled to match the desired profile and slope of the pavement. This process ensures proper drainage and surface smoothness, and the results are always outstanding.

3. Compacting: The reclaimed mixture is compacted using a heavy roller, which increases its density, strength, and reduces voids and moisture content. This process ensures long-lasting and durable pavement.

4. Paving: Finally, a new layer of asphalt is applied over the compacted reclaimed mixture with a paver. The new asphalt layer provides a fresh and smooth surface that enhances the appearance and performance of the pavement, and the results are always impressive.

These steps are tried and tested, and the outcome is always remarkable, making this method a reliable and sustainable solution for renewing pavement surfaces.

Areas We Serve

Providing Paving Contracting to the Central Maine & Southern Maine Areas

All Rights Reserved | Seth Leichnitz